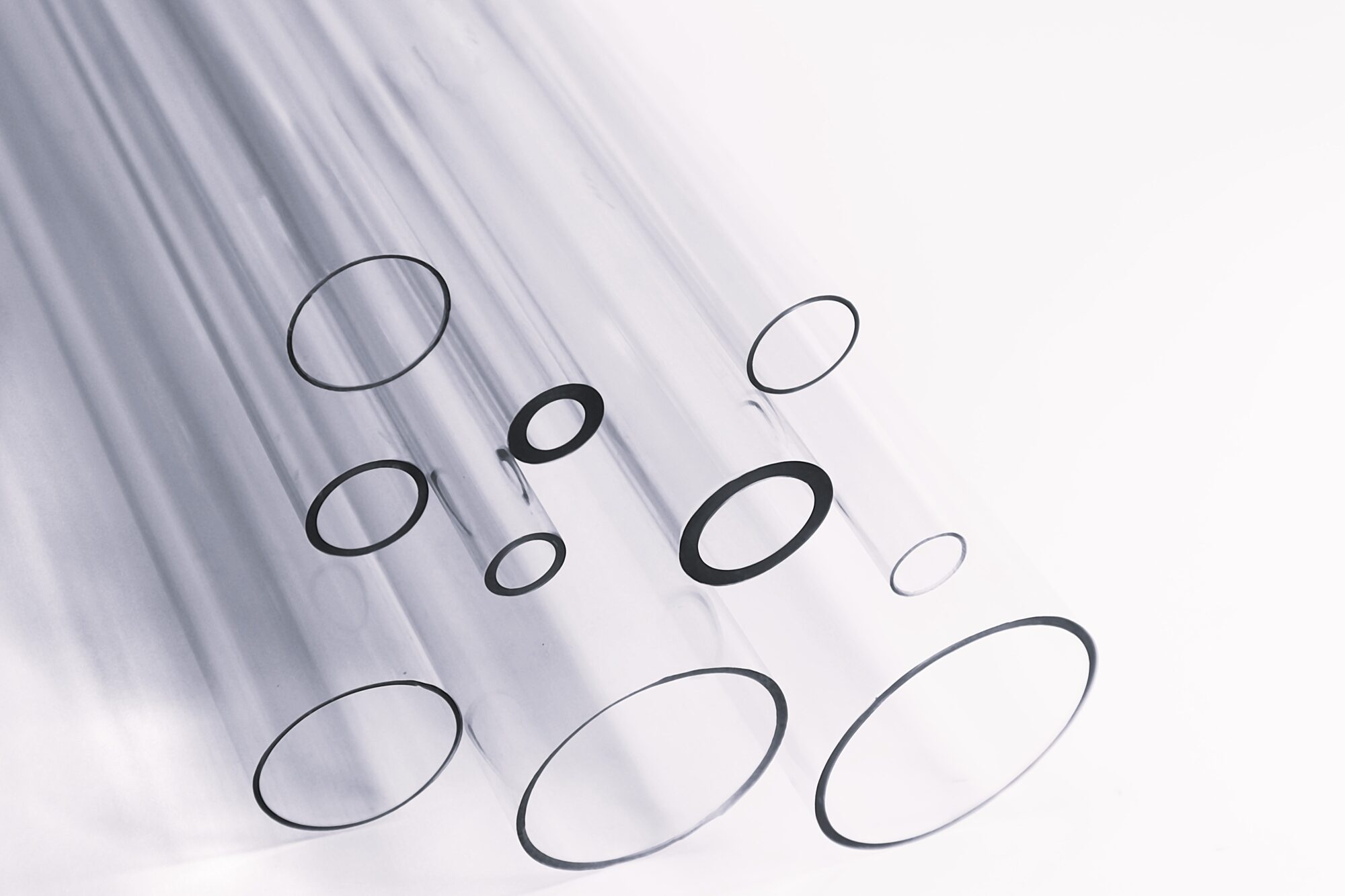

Tubes Tailored

to Specific Applications

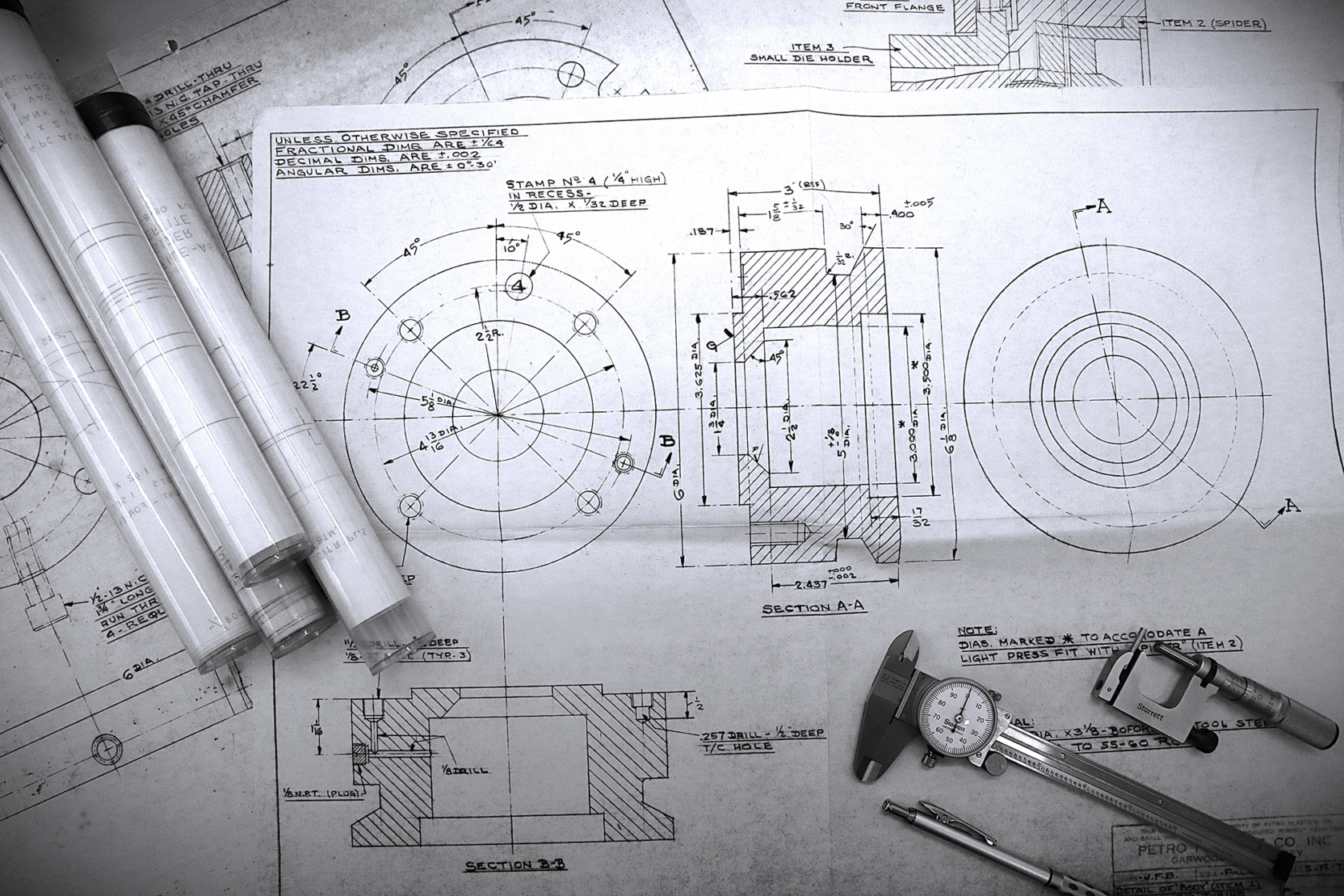

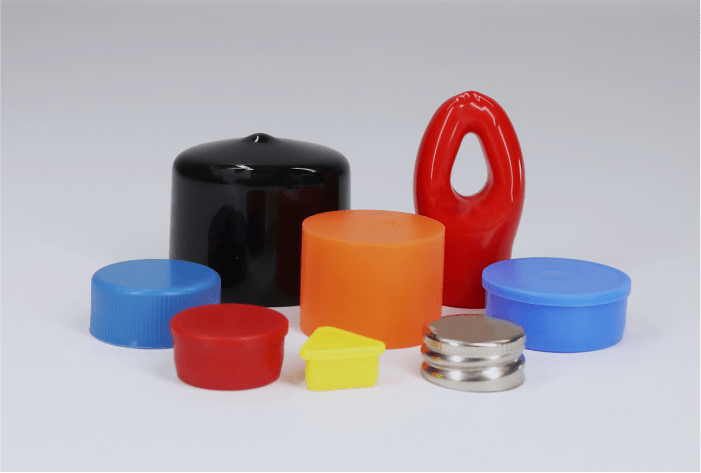

Petro Packaging Co. Inc. manufactures top-quality custom plastic tubes for a variety of unique applications such as product packaging, soil sampling, pneumatic conveying, and point-of-purchase displays. When there are special requirements regarding a product’s design, geometry, or material, a customized tube can be the ideal solution. Custom plastic tubes are routinely developed in-house, and our sales team and engineers will work closely with you to ensure we manufacture your product to its exact specifications.