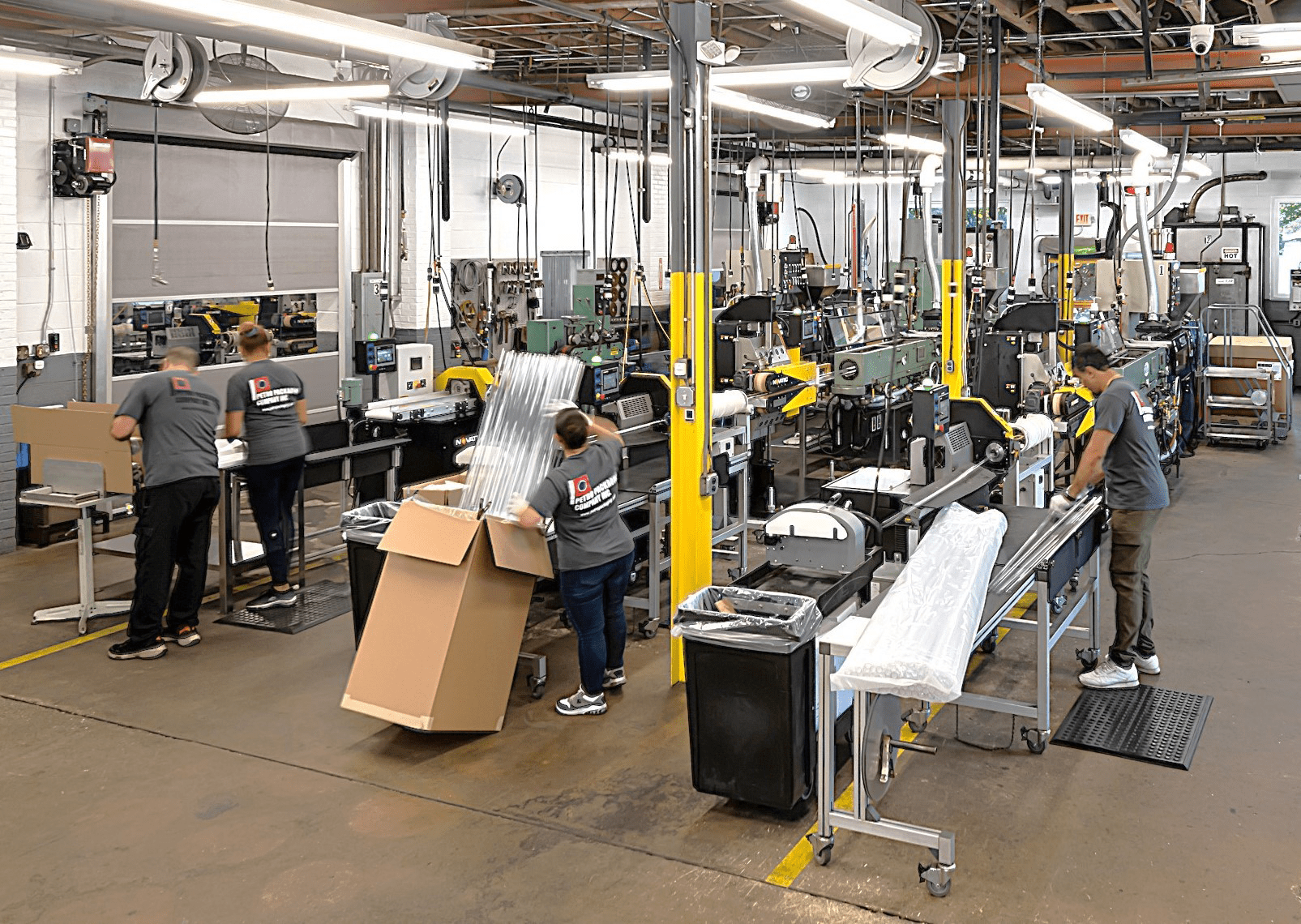

Petro Packaging Co. Inc. is a third-generation family owned and operated plastic manufacturing facility headquartered in northern New Jersey. In the 1960’s we pioneered the use of CAB, CAP, and PETG materials in extrusion, and have since become a renowned name in the plastics industry.

We offer the most comprehensive selection of extrusions for many unique applications, and our sixty-plus years of experience coupled with the dedication to processing a variety of thermoplastic materials has made us your premier extrusion house for plastic tubes and profiles.